Radiant Heater I Type

- Ideal for heating factories, shopping centers, sport facilities, mosques, hangars, warehouses, workshops, fairgrounds, car service stations, etc.

- Only down-focused heat energy thanks to glossy-surfaced reflective sheet placed at the top of the radiant tubes

- Prosestat controlled waste gas inspection.

- Fully automatic flame sensor ignition.

- Low natural gas consumption.

- Long scope.

- Heating without being affected by temperature changes in working areas.

- Average surface temperature of 300-350oC

- Absolutely quiet and safe.

- Length options of 6/8/16 m

- On-site and practical installation.

- CE certificated, production in accordance with ISO 9001: 2008 standards

What is Radiant Heater?

MAKTEK Radiant heater is designed according to a similar heating principle of the solar heating of the earth. Sun’s infra-red rays hit the world, objects and people. Radiant energy is absorbed and every object becomes a heat reservoir and warming begins. With the radiant heater, just like the sun, only the objects and the people are heated, the ambient air of the whole building is not heated. Therefore in a very large, high, wide flattered places like factory, warehouse, stadium , depot etc places with a lot of heat loss, only heats up what is needed; A significant saving in energy is provided.

How Does The Radiant Heater Work?

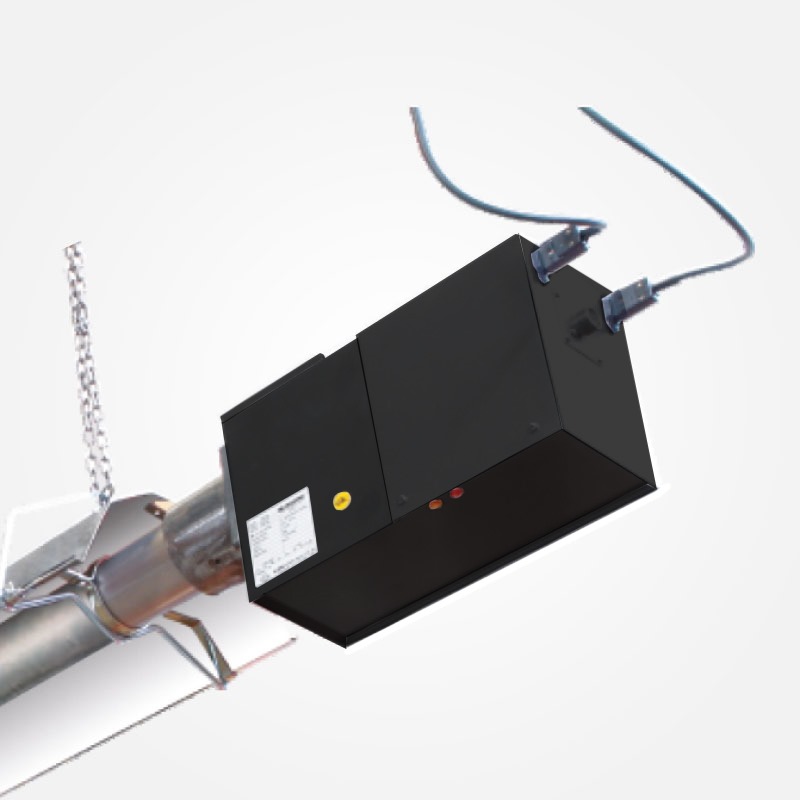

The tubular radiant heater consists of 4 parts: Burner, Radiant Pipe, Reflector and Vacuum Fan. With MAKTEK Radiant heater, the gas burned by the burner is absorbed by the vacuum fan at the end of the system, and is routed through the pipe and thrown out from the cooled point. At this time, the gas circulating in the radiant pipe releases the heat to the pipe. The outer surface temperature of the radiant pipe reaches 300 ° C on average. The radiation spreding from the tube is directed downwards through the reflector on the tube. Rays are turned to heat energy and heating stats when the rays are being directed without afected from air and hit to objects ( machine, human, ground..etc).

WHY RADIANT HEATER?

- Conventional heaters heat up all the ambient air, so people, objects who are in this environment benefit from heat. When the door is constantly open in a building, air changes which cause high temperature losses, occur. Radiant heat is not absorbed by air, so it is ideal for spaces where the temperature changes frequently. Radiant heaters provide significant energy savings compared to conventional ambient heaters.

- The warming air rises. It is very difficult to directly heat work areas using conventional heaters. For example, a building with a high ceiling has cold spots where the heat is relatively low in the work area, while temperatures near the roof are unnecessarily high. Radiant heat is transmitted and directed by infrared rays. By installing the radiant heater correctly in the required points, the cold spot problem in the work areas is prevented.

- Regional heat control with radiant heaters ensures that the working areas are at different temperatures in accordance with the need.

- The radiant heat only heats the human body directly, without heating the whole building. Moreover, the radiant heater responds to the heating needs of the working area much more quickly than other heating methods. Since the time required for warm-up is shortened, a considerable amount of energy is saved and a suitable heating system for modern and flexible working conditions, is established.

- Heating systems operating with the principle of hot air blowing, provide heating by creating air flow in the working area. In production plants where hygiene is important, such heating systems raise dust and dirt from the ground and create unwanted pollution. Moreover, rapid air movements lead to heat loss in the body.